CONDENSER TUBE CLEANING SYSTEM

Heat Exchanger Automatic Tube Cleaning System(ATCS)

ATS-NM condenser tubing cleaning system is an innovated and compact system that giving your chiller life time care.

Introduction:

ATS-NM serial condenser tube cleaning system is an innovated and compact system reducing manual labor and providing a minimum of 8%-22% in energy saving.

The system utilizes pump flow so as to create water turbulence delivering special material sponge balls which are about 0.5mm-1mm larger than the ID of the condenser tube. The sponge balls pass through the tube, scraping off CaCO3, MgCO3 as well as other material caked on the tube surface.

Energy Saving Rate:

The system will extend the life of the condenser and improve teat transfer.

Energy Saving Rate= (COP2-COP1)/COP1X100%

In some cases the ESR can reach 28%

What’s New for ATSEA NM-300:

- Easy installation and does not change the CW pipe

- Compact pipe layout based on unique design ball traps

- Smart PLC control

- Certain cases can be designed as 2in1(one system can operate two condensers)

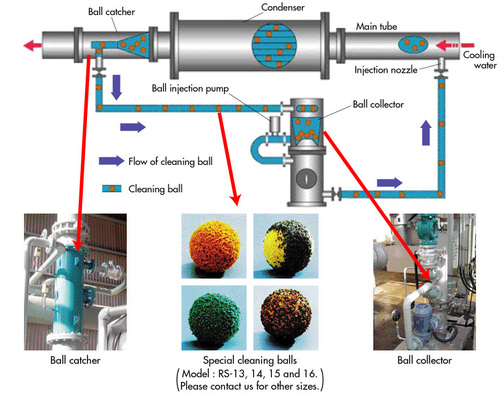

Working Principle:

The sponge balls (in the ball collector) are delivered by the pump from the inlet pipe of the condenser through the condenser tubes. The sponge balls pass through the tubes and removes any film and caked-on material on the tube surface. The balls will be gathered in the ball catcher, then returned to the collector.

All balls are cycled in a closed loop and never allowed to escape the system.

See Working principle and sponge ball photos